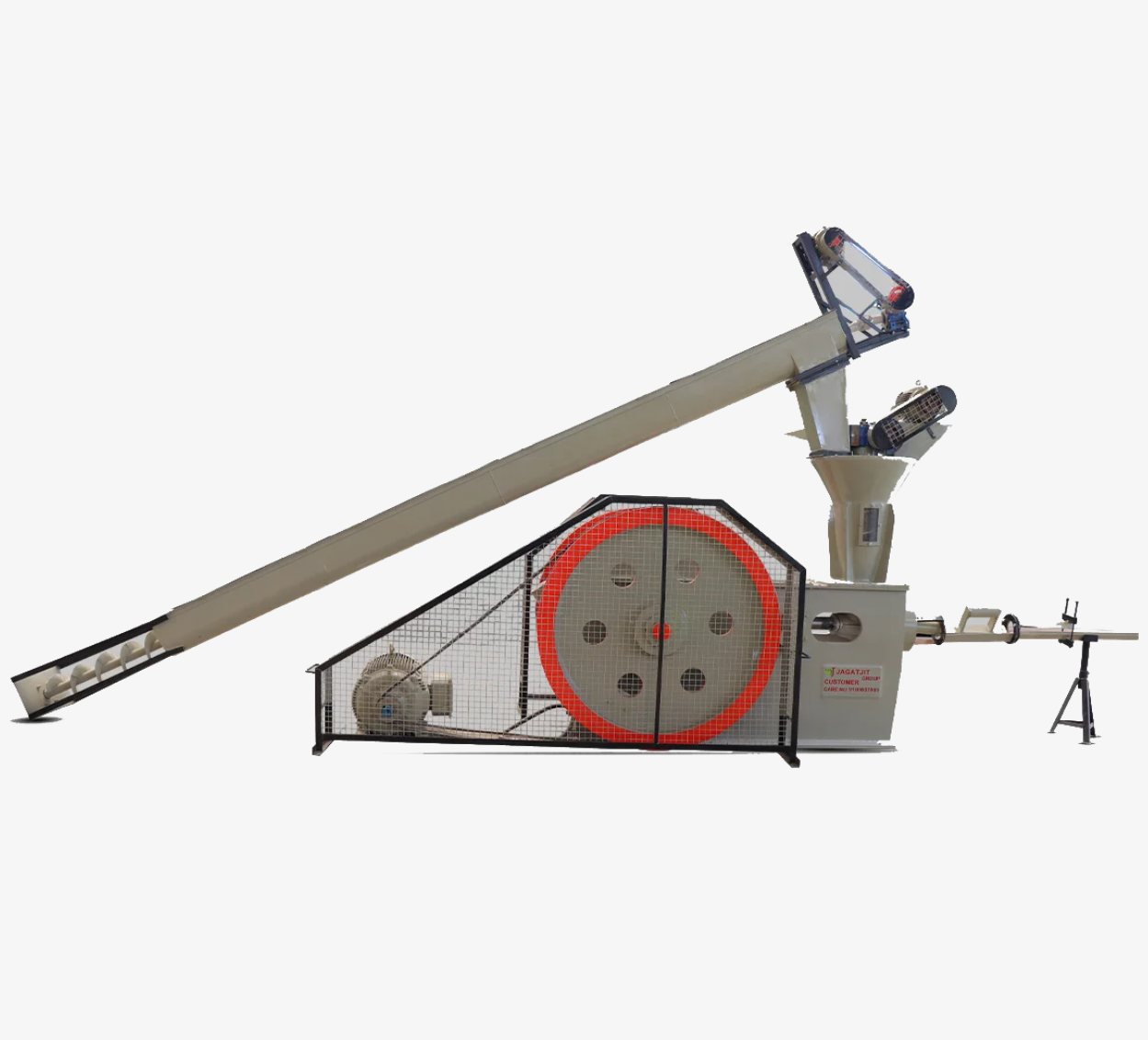

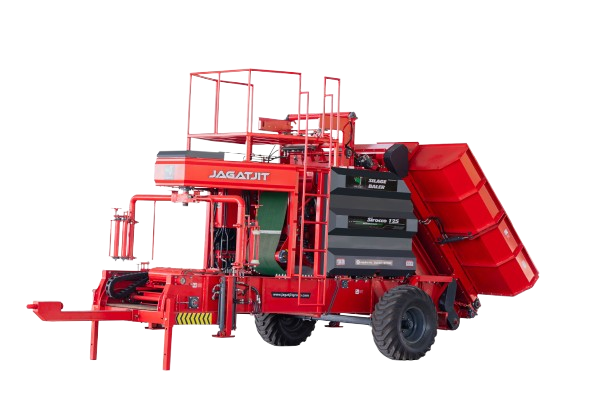

Stone Separator

High-Capacity Sorting

Efficient impurity removal

Ensures Equipment Protection

The Jagatjit Stone Separator is designed to remove stones, metal particles, and heavy impurities from biomass raw mate

*The company reserves the right to change specifications without prior notice.

Key Features:

- Efficient separation of stones and heavy debris from raw material.

- Adjustable settings, ensuring optimal impurity removal.

- Durable stainless steel body, ensuring long-term performance.

- Reduces wear and tear on biomass processing equipment.

- Essential for high-quality briquette and pellet production.

Quality is an integral part of JAGATJIT GROUP Business Principles. These principles guide our actions to deliver products and services that are safe, compliant and preferred. They are essential for the achievement of our ambition to be recognized and trusted to offer products and AFTER SALES SERVICES that enhance the quality of farming machinery and contribute to boost AGRICULTURE ECO system.

|

Model |

Production Capacity |

Total Power Required |

|

Jagatjit Pneumatic Stone Separator -JPS 1.5 |

Upto-1500 kg/h |

15 hp/11.18 kW |

|

Jagatjit Pneumatic Stone Separator -JPS 2.5 |

Upto-2500 kg/h |

22 hp/17.89 kW |

|

Jagatjit Pneumatic Stone Separator -JPS 4.0 |

Upto-4000 kg/h |

41 hp/30.57 kW |

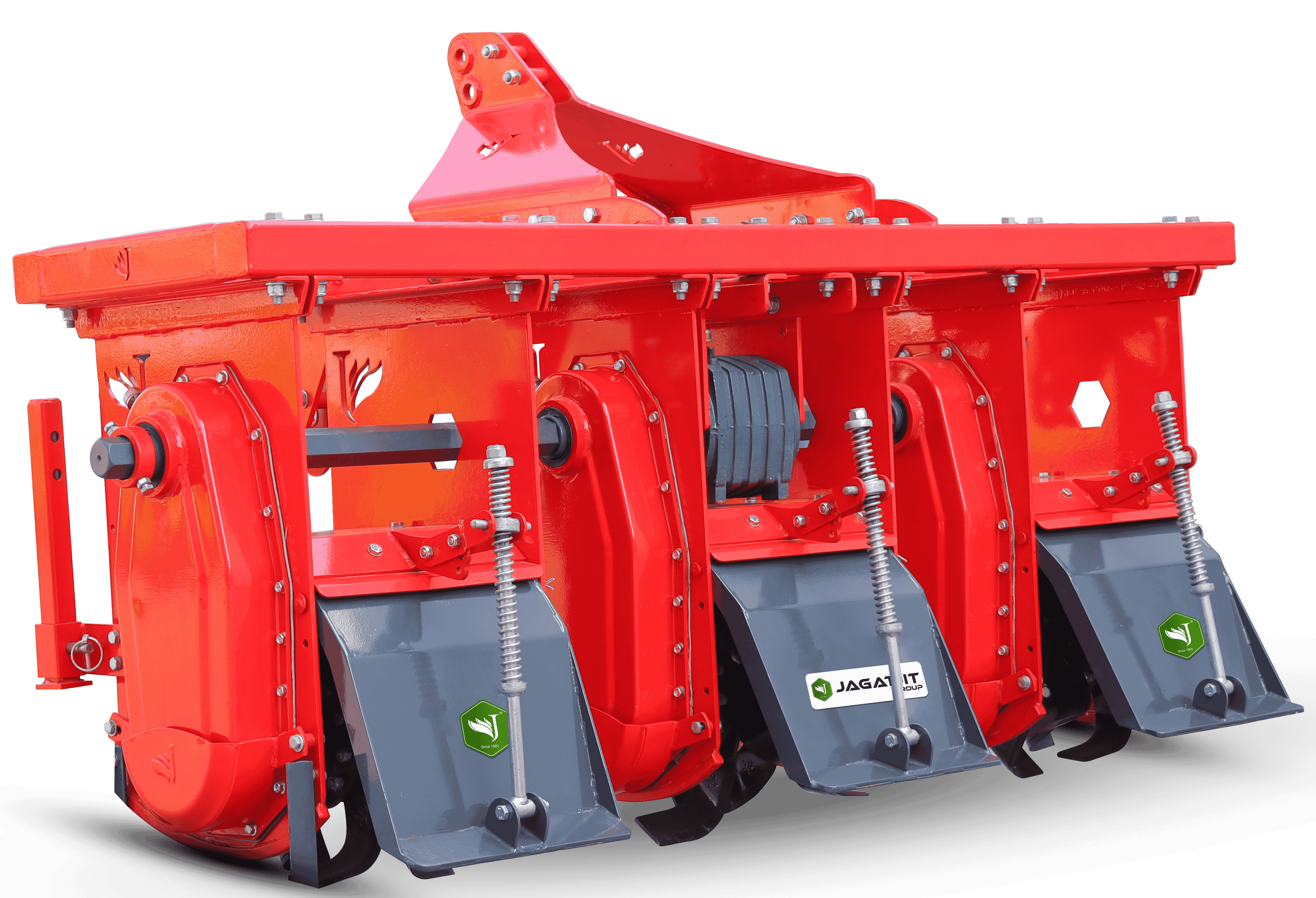

| Particulars | Description |

|---|---|

| Total Area Required | 1,000–4,000 Square Feet |

| Machine Buildup Area | 20 FT. X 15 FT. (L X B) (For One Machine) 20 FT. X 25 FT. (L X B) (For Two Machines) |

| Buildup Shed Area for Storage of Briquettes | 50 FT. X 15 FT. (L X B) 30 FT. Height |

| Foundation Required | Yes |

| Foundation Drawing | Will be provided by Jagatjit Group® |

| Foundation Road with Bolts for Machine & Electrical Main Moto | Will be provided by Jagatjit Group® |

| Particulars | Description |

|---|---|

| Briquette Press Model | Dual Feed ™ Jagatjit Group® 90 |

| Production Capacity | On briquettes up to 2,400 kg/hr (on granulated raw-material only) On pellets up to 1500 kg/hr (on granulated raw-material only) Production may vary; depends on the combination of feedstock |

| Power Required (Total Power Required: 92 HP / 67.90 kW) | 1 HP electric motor on oil lubrication system to maintain the oil flow 75 HP electric main motor attached with pulley to drive machine flywheels 5 HP x 2 electric motor on side feeder for feeding the material inside the machine 3 HP electric motor with reduction gear on material drifter 3 HP with VFD drive to control the in-feed speed of raw material |

| Machine RPM | 200 RPM |

| Finished Good Diameter | Biomass briquettes: 90 mm (± 5%) Biomass pellets: 8 mm, 10 mm & 12 mm |

| Finish Good Shape | Cylindrical |

| Finish Briquette Length | Briquettes 20 mm to 350 mm approx. Biomass pellets 10 mm to 50 mm approx. (Length of final product may vary as it depends on the raw-material mix, its blend proportion & type) |

| Number of Reduction Gears Used | 4 gears used for controlling the speed and maintaining the torque of different shafts |

| Sensor System | Equipped to safeguard from any mechanical failure, (in the case of bush heating, due to non-supply of oil, etc.) |

| Raw Material In-Feed Size | Granulated raw material only, if size is bigger than it needs to be grinded before feeding into the machine |

| Raw Material Moisture | Moisture in material should be between 8%-12% |

| Manpower Required | Operator-1, Labour-2 |

| Visibility & Maintenance | Mirror acrylic sheet is installed on machine's top body to maintain the visibility of oil & inner machine moving parts |

| Cooling System | To cool down the oil temperature and other machine body parts |

| Oil | Machine oil chamber will be full of required amount of oil |

| Fixation of Machine | Foundation rods will be provided with bolts to fix the machine |

| Nylon Belts (V-Belts) | 7 nylon belts (C grade) to drive the machine wheels with safety guards 2 nylon belt (C grade) to drive the in-feed conveyor with safety guards |

| Rotating Parts Safety Guards | Will be provided with machine to safeguard personal working from rotating wheels, motor pullies, etc. |

| Parts Attached | Die holder attached with all the inner parts & cooling water pipes Feeder box, RAM & other consumables parts are attached to the machine |

| Screw Conveyor | 1 screw conveyor (20 feet long) with the reduction gear (for in feeding the material into machine) |

| Cooling Line | 1 cooling line (15 feet long) with 3 stands |

| Electrical Motors | Make: Siemens, Crompton |

| Electrical Panel | For operating and control of machine (Make: Schneider) |

| Electrical VFD | 1No. used on in-feed screw conveyor, Make: Schneider |

| Electrical Cable & Wires | From briquette machine to electric panel 20 feet long |

| Reduction Gears | Make: Spaggiari/Gear House/Motovario |

| Bearings | Make: NRB, HKG/NBC/SKF |

| Tool Kit | For calibration of main components |

| Sr. No. | Item Name | In Machine (Qty.) | Extra With Machine (Qty.) |

|---|---|---|---|

| 01. | Pellet Die | 1 PC | - |

| 02. | Briquette Die & Collar | - | 1 PC |

| 03. | Split Pipe | - | 1 PC |

| 04. | Ram Cap | 1 PC | 1 PC |

| 05. | Ram Cap Type | 1 PC | - |

| 06. | Tikki with Tikki Bolt | 1 PC | 4 PC |

.png)

%20(1).png)

.png)